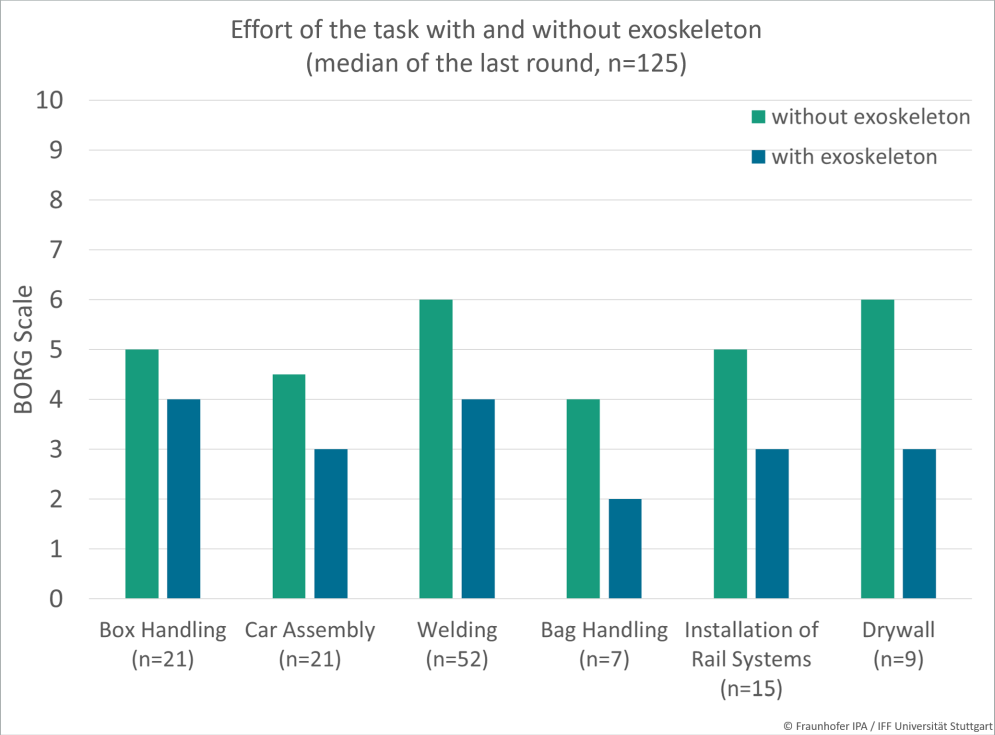

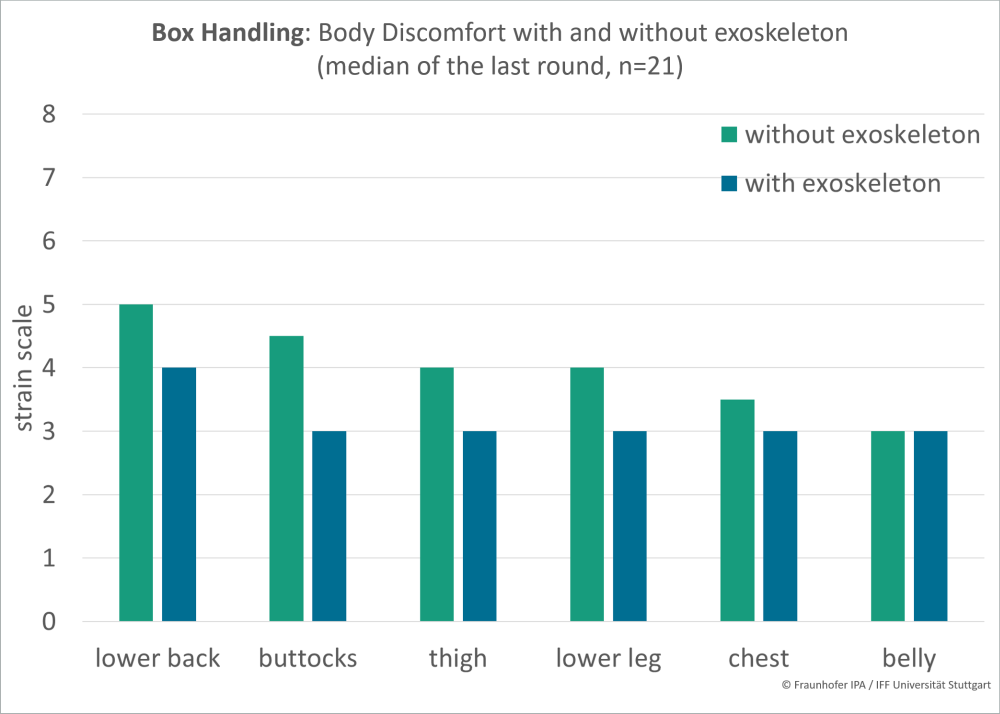

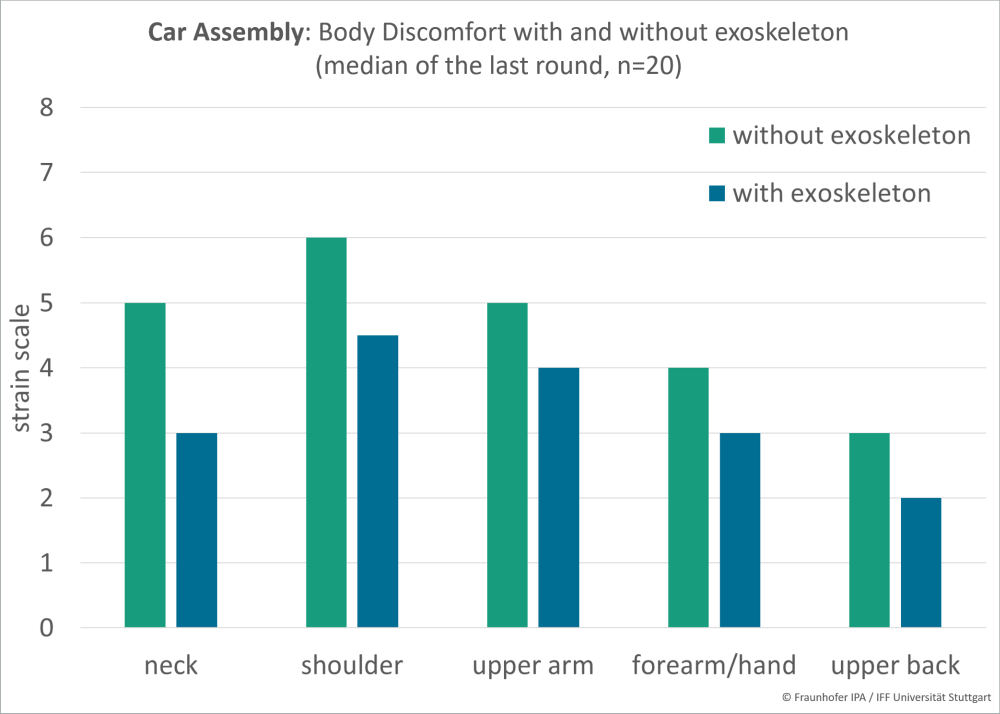

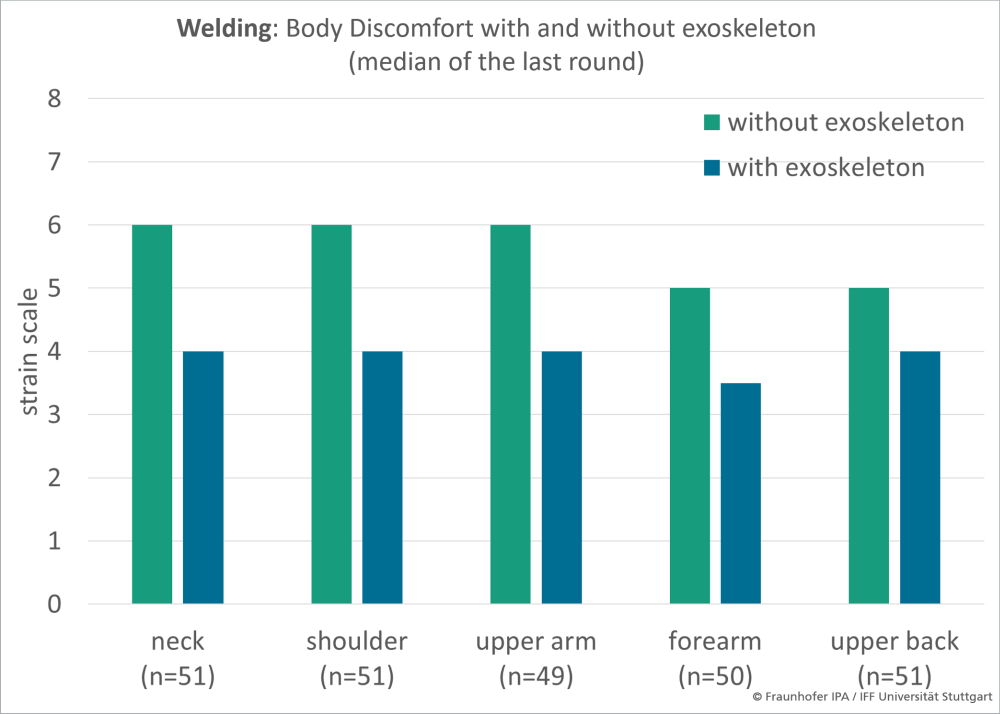

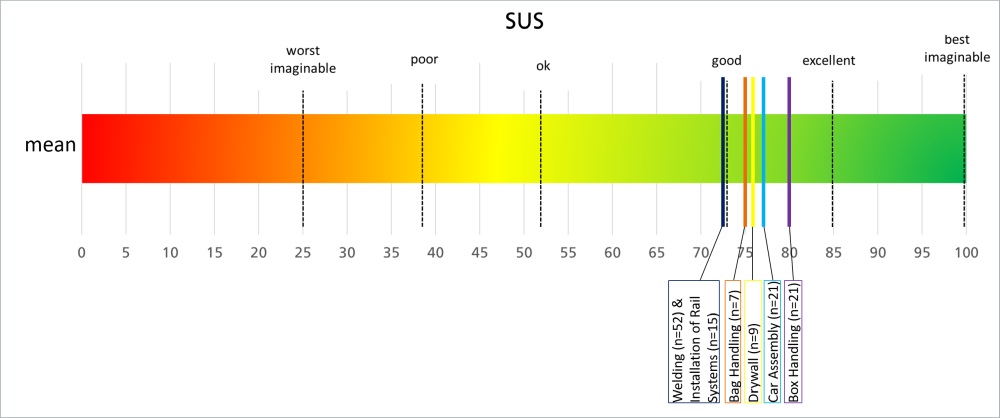

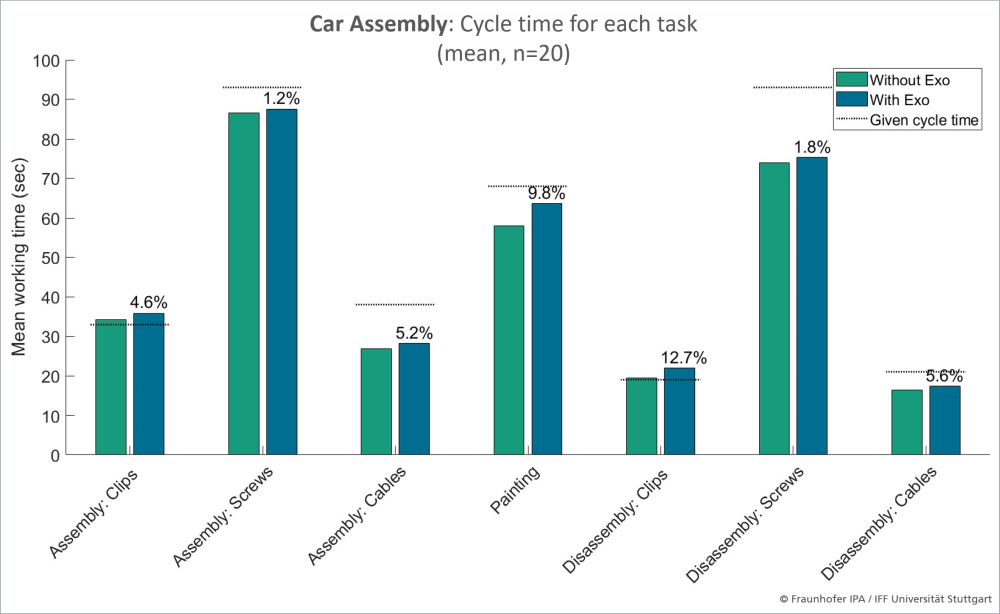

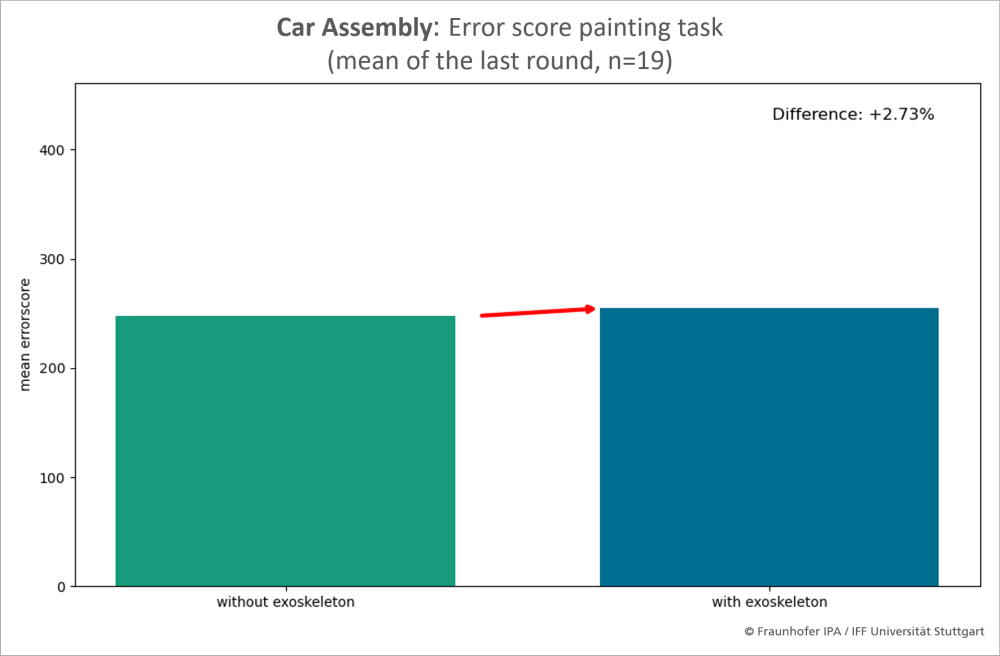

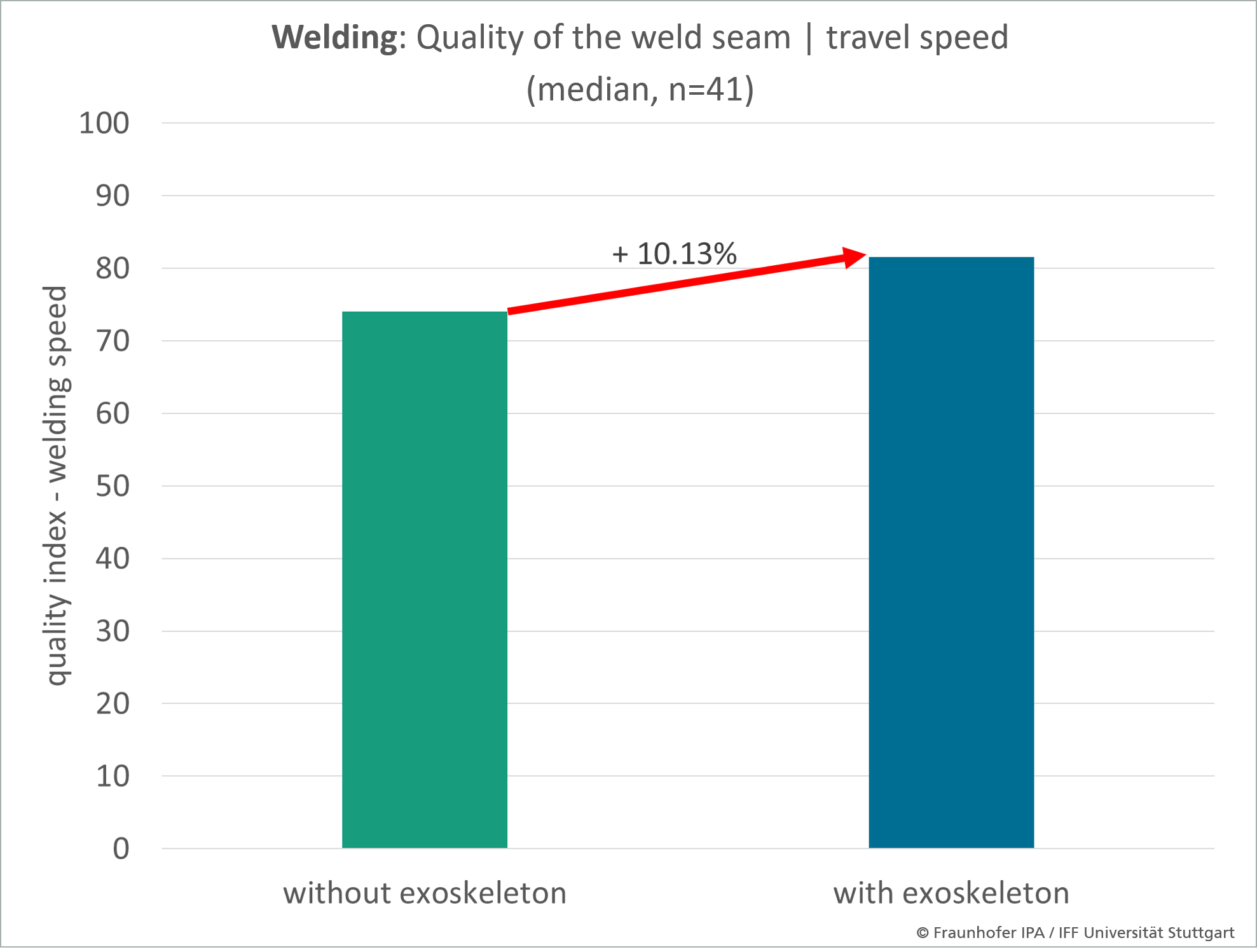

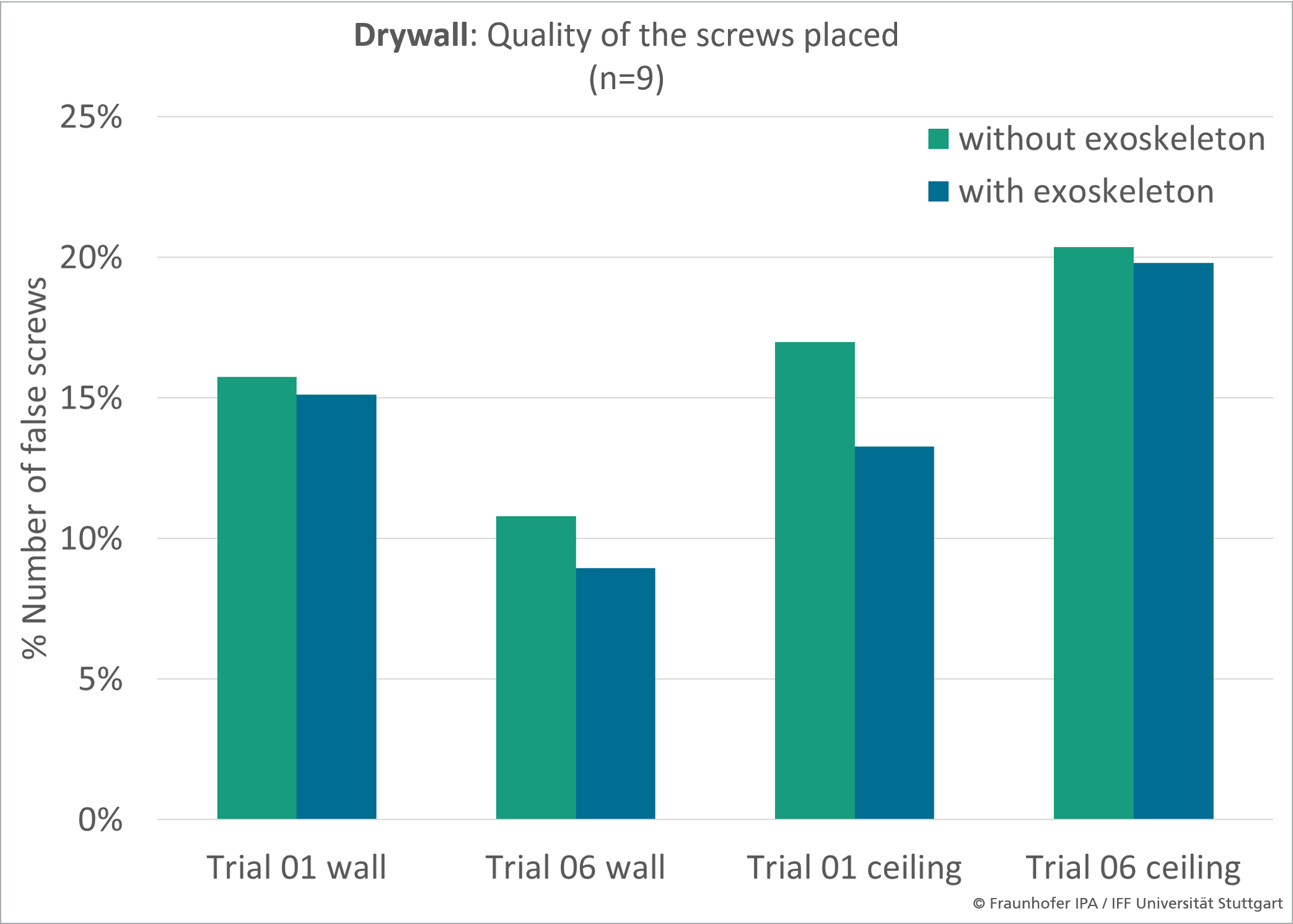

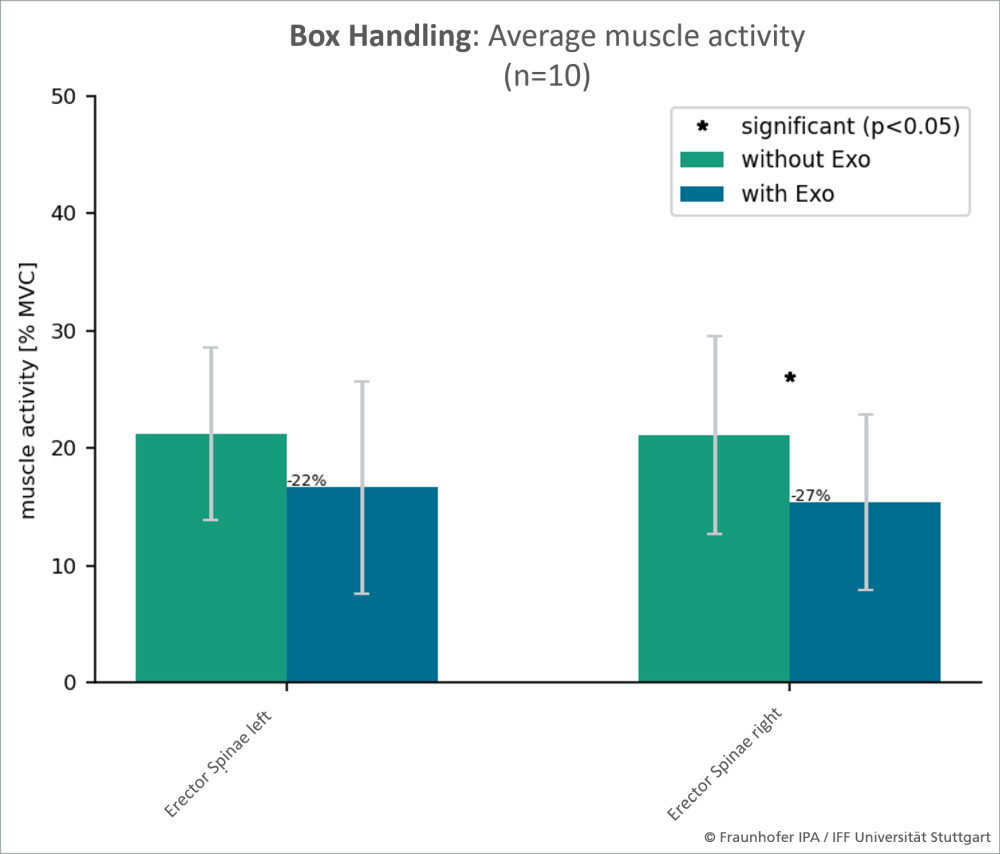

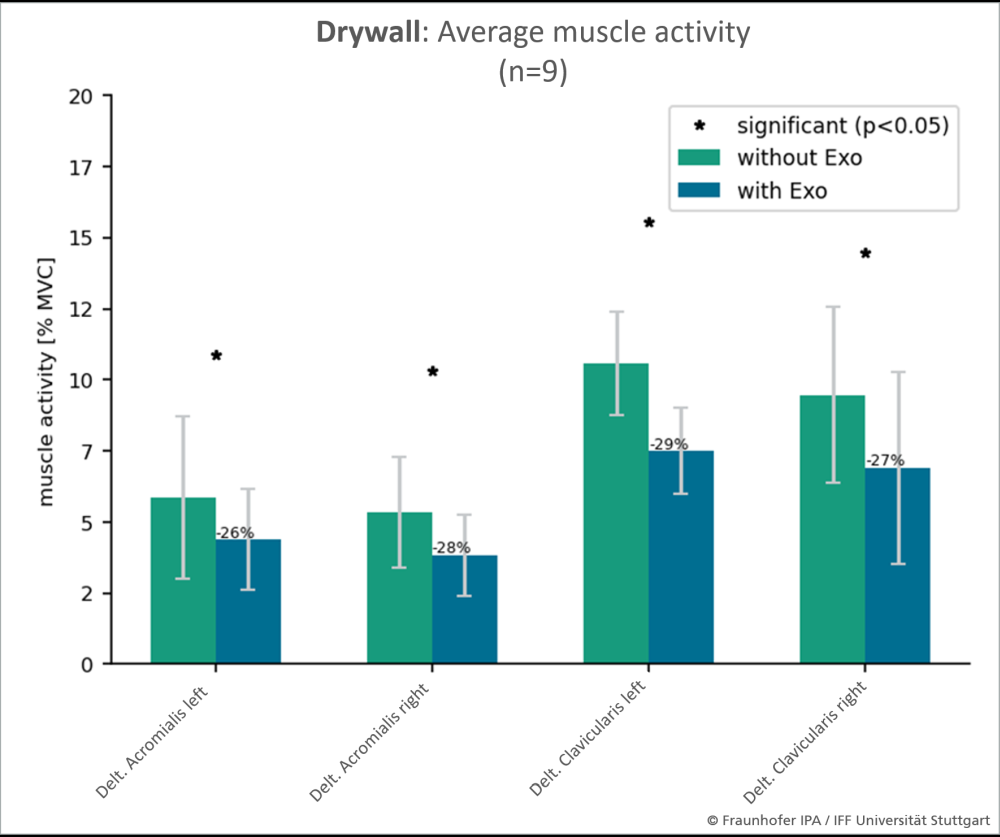

From 2021 to 2023, a total of 125 subjects participated in the study.

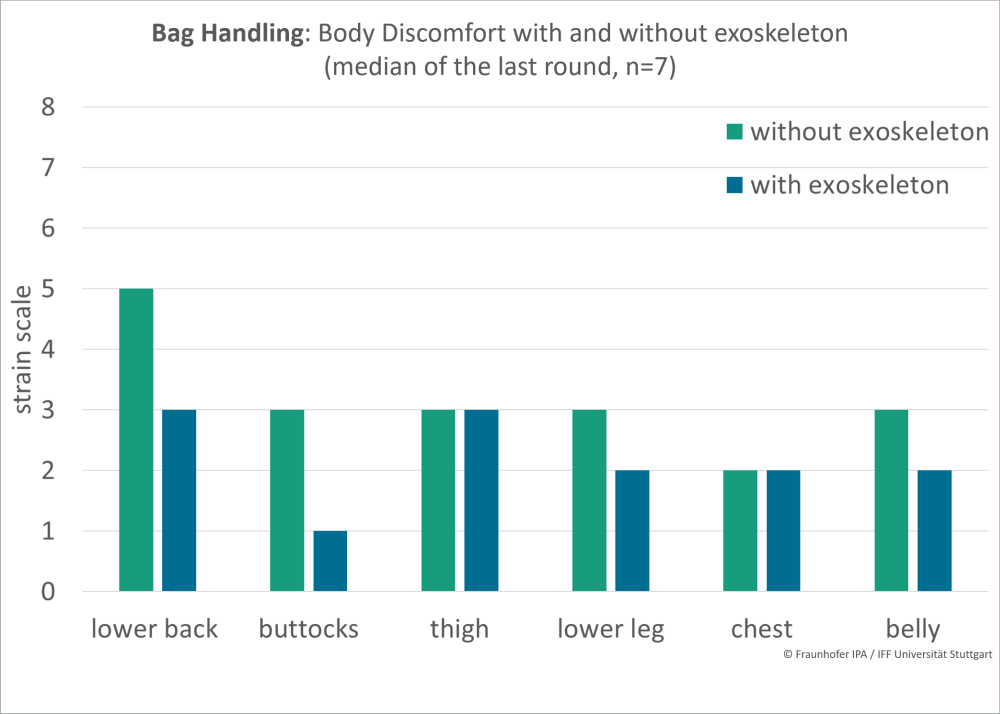

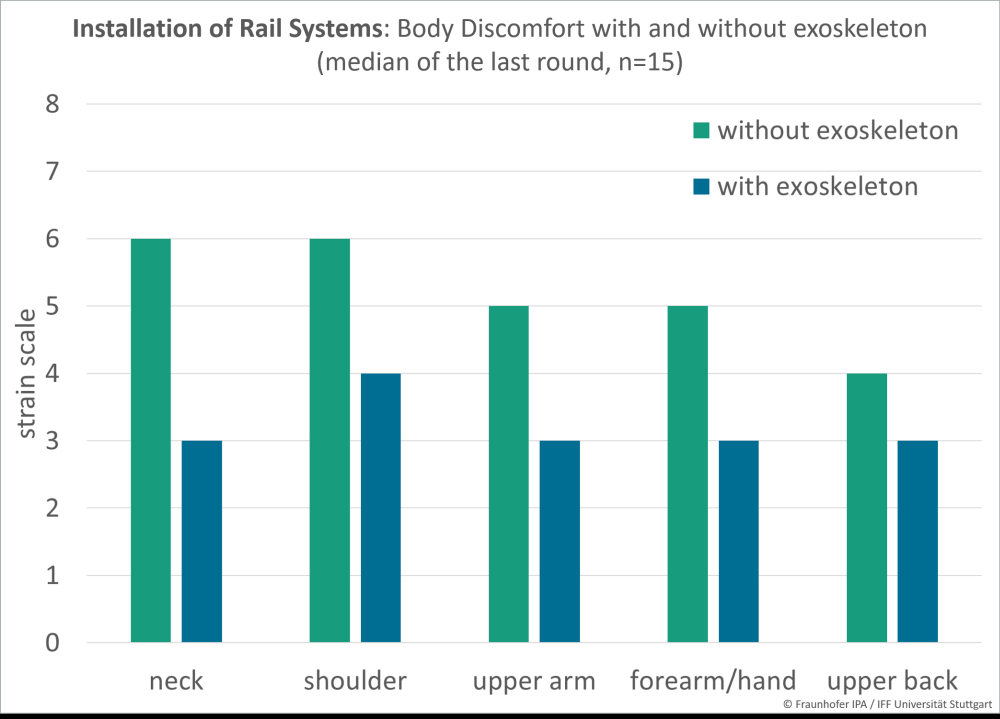

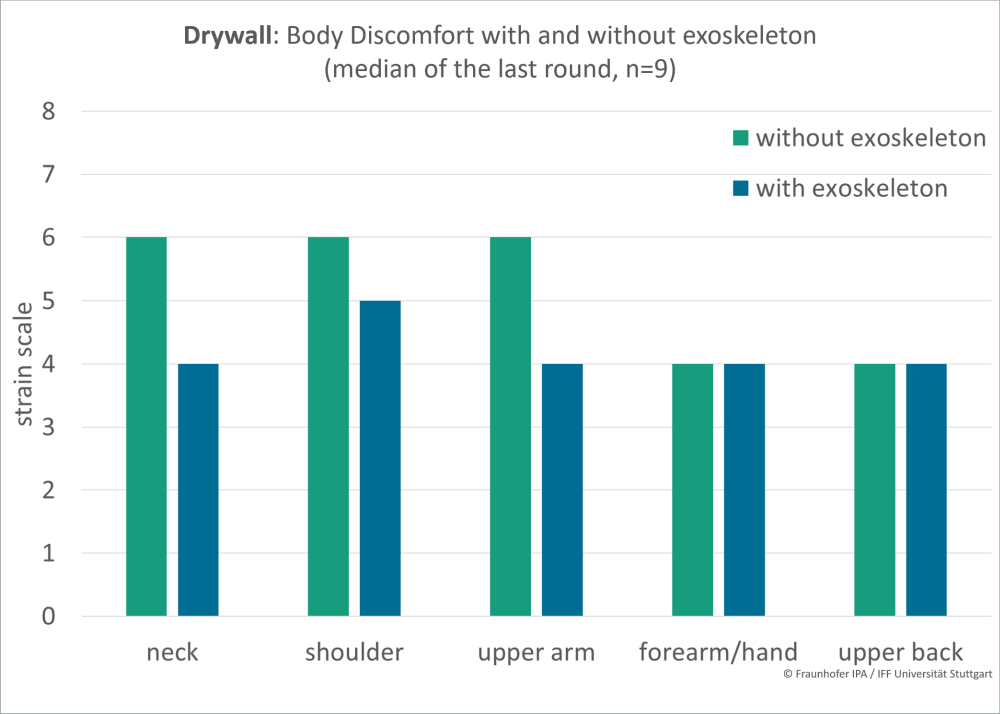

(Box Handling (Logistics): n=21; Car Assembly (Automotive): n=21; Welding: n=52; Sack Handling (Logistics): n=7; Installation of Rail Systems (Construction): n=15; Drywall (Construction): n=9)

The subjects were young men and women aged 17 to 34 years and an average age of 24 years, who were familiar with the work they had to do in the Parcours.

The experiments took place at Audi Education Lab, Neckarsulm, Wilhelm Maybach Berufsschule Stuttgart, Messe Duesseldorf, SLV Nord Hamburg, and Steinbeisschule Stuttgart.

Exoskeletons from different manufacturers were randomly assigned to the subjects to maintain market neutrality and not indicate the advantages and disadvantages of a particular system.

We thank all the wonderful contributing people and institutions for making this great experiment happen. The CONTRIBUTING PARTNERS List includes them all.

Fraunhofer IPA & IFF University of Stuttgart

Fraunhofer IPA & IFF University of Stuttgart