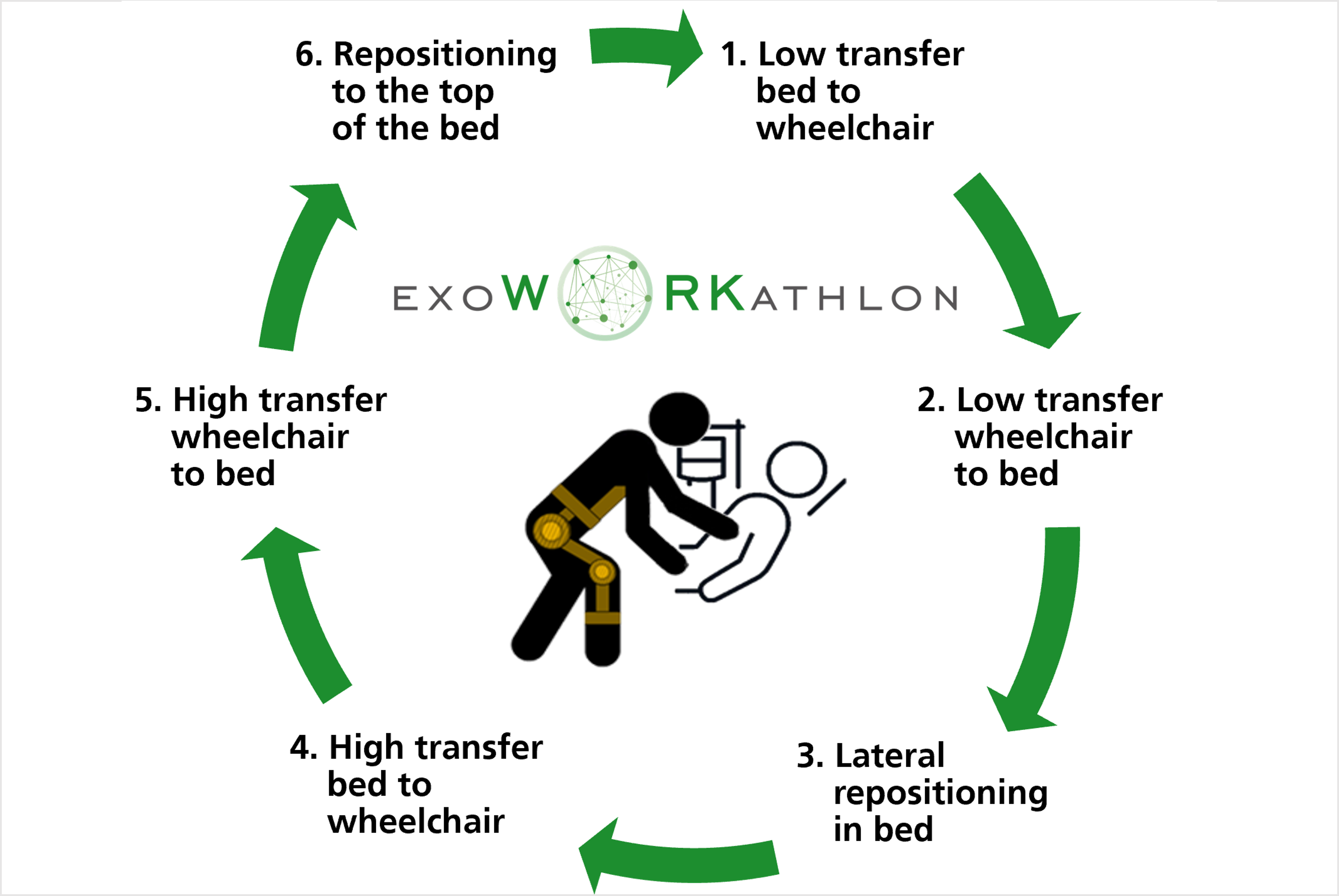

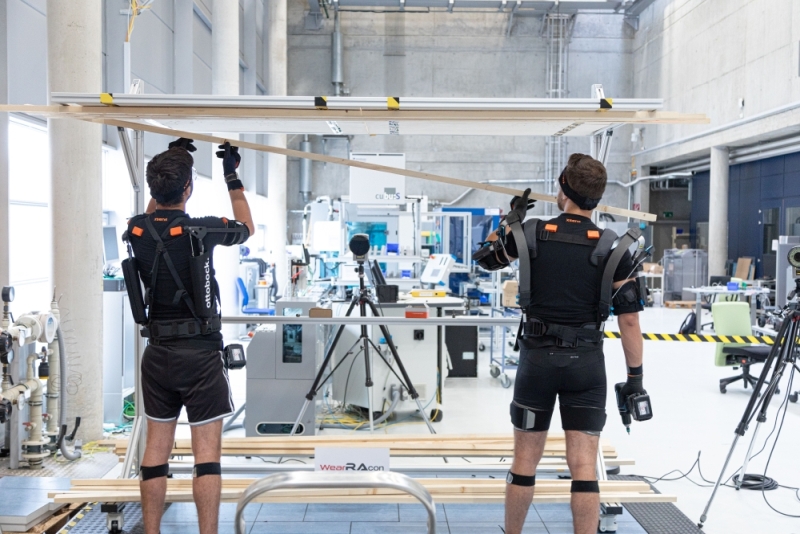

Specific Parcour modules are developed with industrial relevance to simulate realistic work processes. A single professional user runs each Parcour

twice – once with an exoskeleton and once without an exoskeleton. The exoskeleton, as well as the task execution with and without exoskeleton, are randomly assigned to the participants.

The paper "Exoworkathlon: A prospective study approach for the evaluation of industrial exoskeletons" by Kopp et al. (2022) provides a detailed description of the background and methodology of Exoworkathlon.

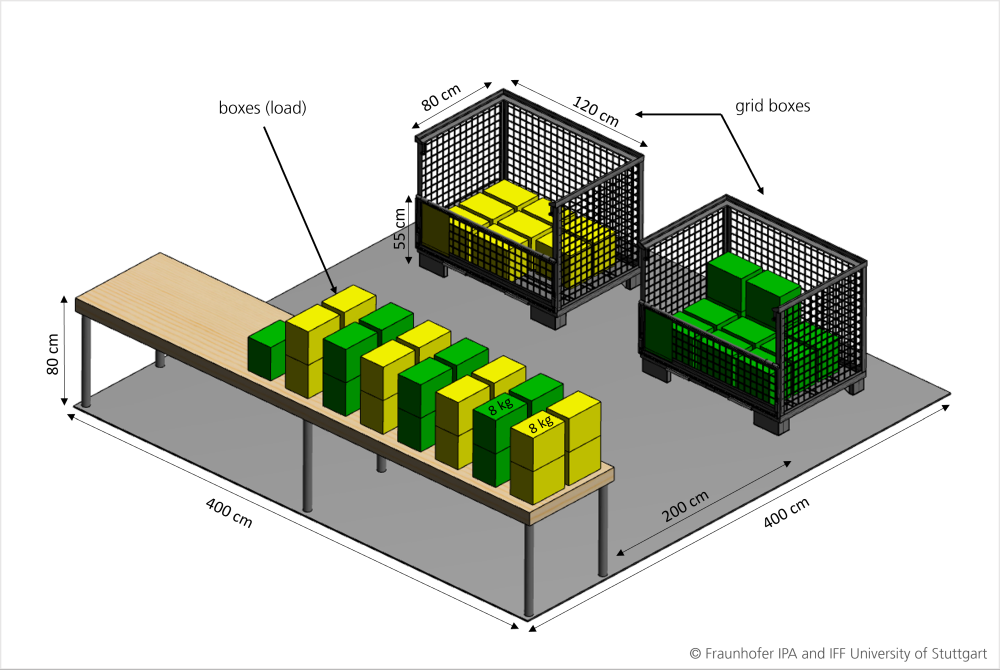

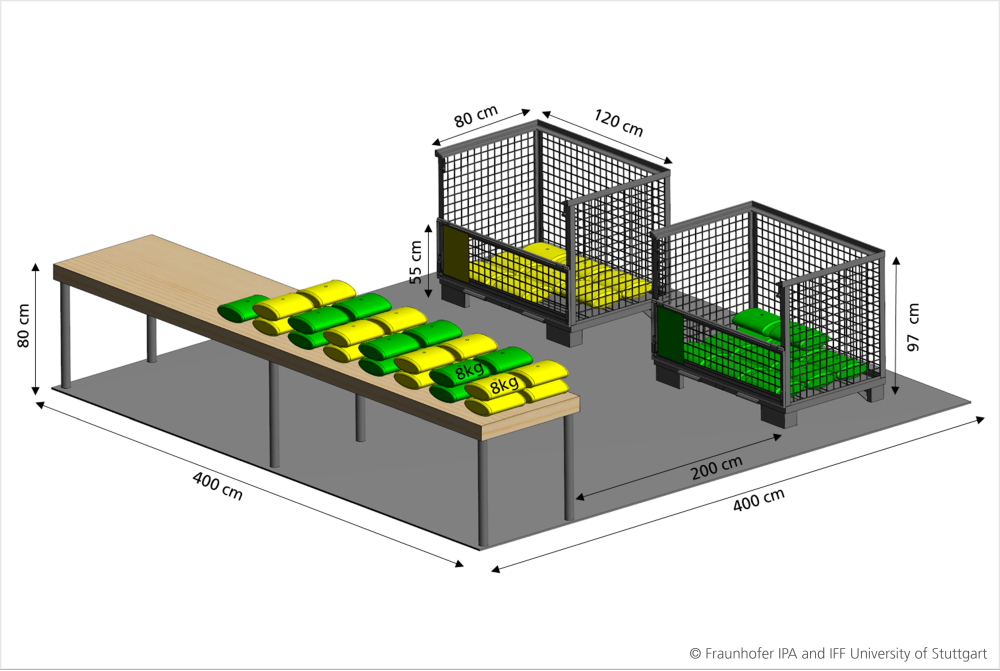

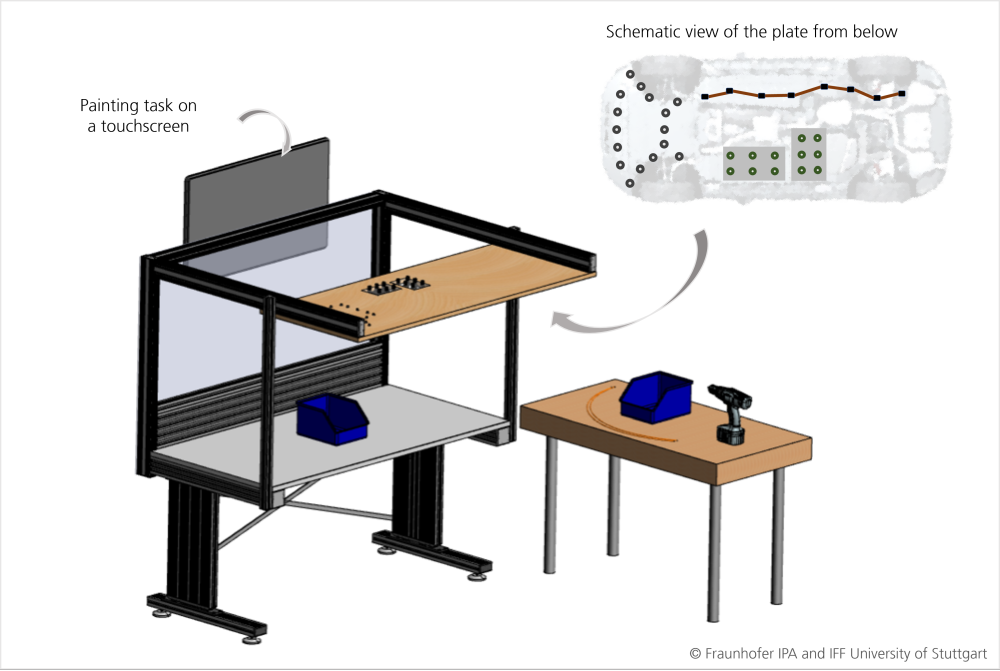

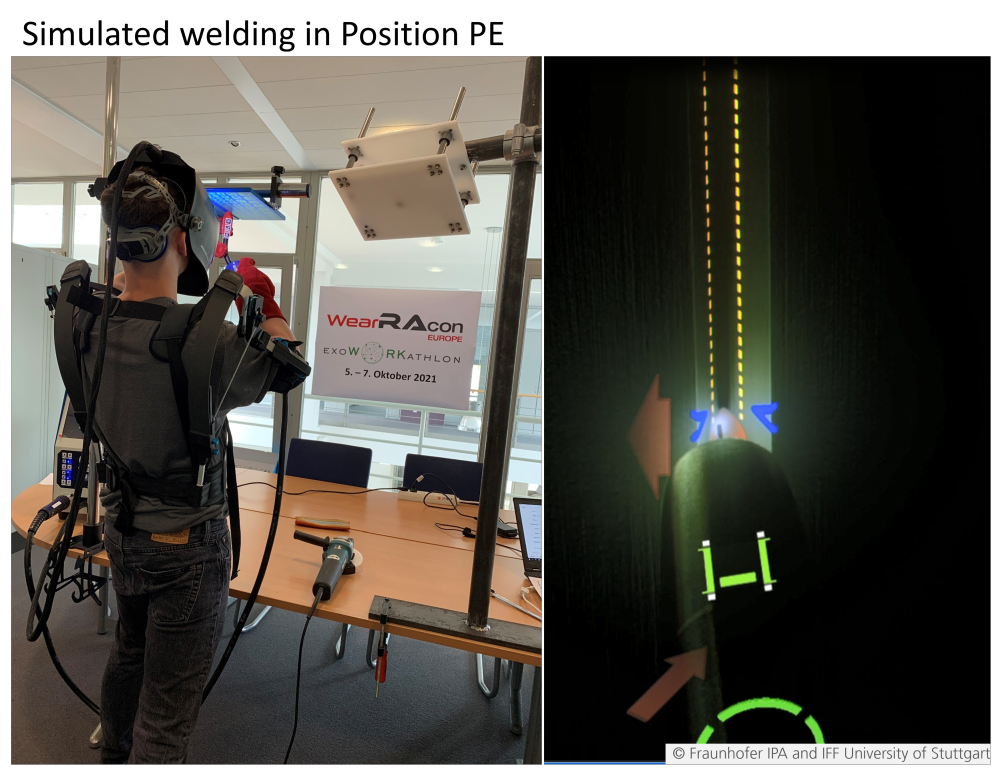

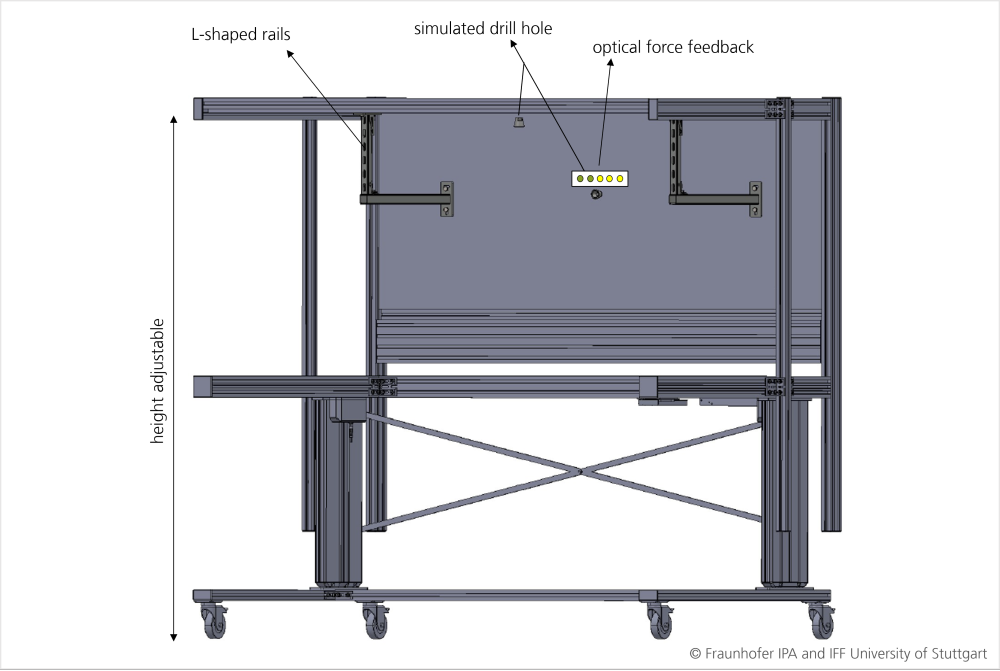

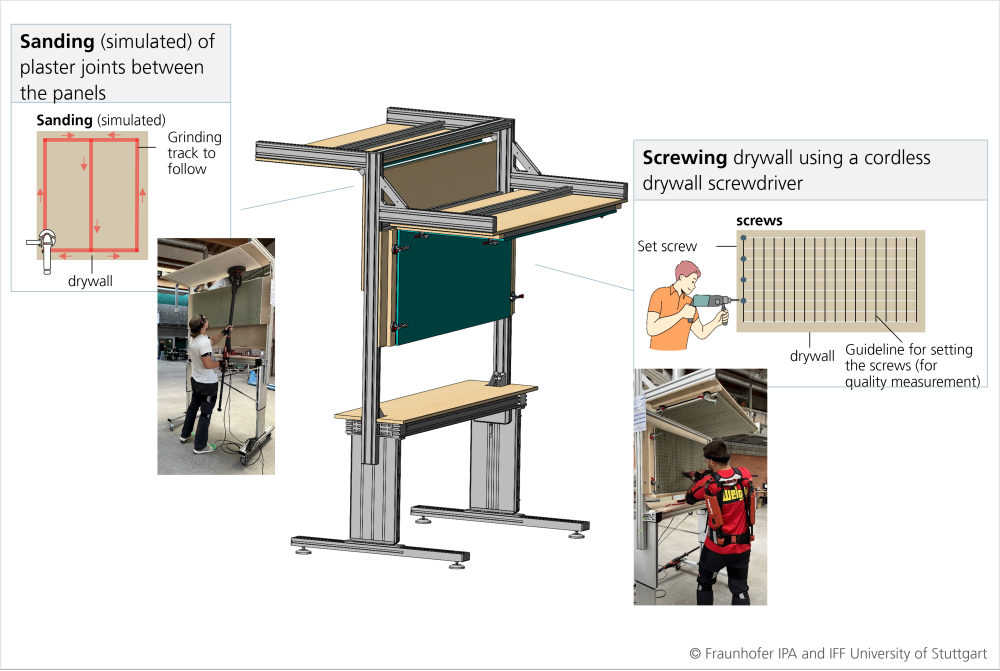

Each Parcour is developed with experts from the corresponding industries and health sectors. Its tasks must be realistic, feasible, and relevant to exoskeleton use. So far, six Parcours from different industries, such as Logistics, Automotive, Welding, and Construction, have been included in the EXOWORKATHLON®.

Different evaluation methods are used. Subjective user feedback scoring is a key element. A comparison of intra-individual differences is generated. The exoskeleton manufacturers that have already participated are mentioned, but the specific exoskeleton used is kept anonymously in the output statistics.

Fraunhofer IPA & IFF University of Stuttgart

Fraunhofer IPA & IFF University of Stuttgart